HoneyBee Mega Drive Controller Directions At 45°?

I've been fixing a bulk load of SMS/SMS2/MegaDrive stuff and one of these controllers was thrown in with a note stating "Erratic Directions."

Externally everything checked out, so I opened it up and continuity-tested the cable and plug. No issues there! I tested it again on the SMS2 that I had available and realised that I could get the directions I wanted by mashing in the corners of the D-PAD... what gives? I opened it right up...

What's going on here? The actual D-PAD circuit board contacts aren't in an NESW orientation? They're a box, flat on the ground? I continuity-tested for the UP button and it turns out to be the top-right pad. Just to confirm I wasn't bonkers, I put the rubber-contact-thingy back in the D-PAD housing and sure-enough, the pads match the pads!

So wait, to get the direction I want, I REALLY DO have to mash in the corners of the D-PAD. This is BY DESIGN. I wasn't a very good gamer when I was young, and this system was available to me at that time. The range is Competition Pro, so I assume this was an answer to the kiddies who held the controller at 45-deg in their left hand and mashed the other buttons with their right? Google is giving me nothing.

NOTE: just looking at that first picture, you can see where your thumb is meant to rest. This easily hints at where UP is. Can someone please point me to documentation where this is made clear that the directions are 45-deg clockwise rotated?

Build Your Own Macintosh Classic!

Man, somehow I google'd across this link on creating your own Macintosh Classic and decided I'd do it myself. I'd already sunk cost into my own Kickstart'd Creality CR-6 SE printer and decided wtf, how hard can it be? The article even had a BOM that included all of the other physical components required. I placed the order, it arrived, COVID happened, box was stored, everything was forgotten.

Come Melbourne's lockdown #6 and I'm bashing through everything in the received-but-not-touched list. What to do first? Print the case. If that doesn't work, then who could care less about the tech purchased?

And with the printing, I screwed up! Make sure to configure your print settings with supports everywhere, not just 'touching base' or whatever the boring default is, as it won't work. I had to scrape the top inner frame of the display window to get it to not look too saggy!

The floppy disk is an insert and, as per the instructions, I added a white sticky-label to make it actually look like a floppy label. Once in the case it looks great!

Required Hardware

First off, we'll be using a Raspberry Pi Zero W, an old IDE cable and a 640x480 VGA screen for inside the case. Outside, some form of USB Keyboard and Mouse will be required to get everything installed. The Pi Zero is a very bare-bones unit and you'll need to get out the soldering iron, find some headers and solder up the GPIO interface.

From there, you just need to plug in the IDE cable and test it out. I did this first with just the standard RasPi install.

It worked fine... and was hilariously small.

Installing RetroPie

So, long-story-short, I tried the latest RasPiOS + yada and although the UI was lovely, the speed was shite. I then tried compiling my own BasiliskII and it just chuggggged. So, what's the answer? THIS IS THE INTERTUBES, someone has already done this: let me present to you RetroPie! Now, this is an amazing front-end + engines for Linux, to the point where configuration is out-of-the-box, but not so much for what we're about to do.... there's a bit of screwing around required!

First off, to get that Pi Zero W to boot, you're going to need to flash an SD card. On Windows, use the official Raspberry Pi Imager and choose RetroPie from the Emulators sub-menu.

Grab the card, a USB KB/Mouse and a display and boot the Pi. If everything works, you should be at a prompt to configure a gamepad?!

This was a little confusing for me as I didn't really care for a gamepad on this system at all. RetroPie expects you'll be playing Bubble Bobble, Snow Bros and Metal Slug, so it demands a controller configuration on installation. And so, with our goal being to play A-Train on System 7.5.5, we don't need a gamepad, but we'll still need to configure a device. This device will be a stock-standard keyboard and we'll need to tread lightly when mapping the buttons.

To get started, hold down a key on your keyboard for about 5 seconds. From there, please map the D-PAD directions to the arrow keys on your keyboard and then start=enter and select=space. From there, you can either spend time holding down any key to skip the association or just choose any key (don't choose the same key each time) to map to the millions of buttons. Once you succeed, the OK button will be highlighted and you get to press the key you mapped to button A.. do you remember?

If all is well, you'll have hit the screen above. This, in all it's glory, is RetroPie as a shell, with no engines underneath. Before we install engines, let's make sure we have full connectivity. Make sure that Configuration is showing under the RetroPie banner (use left and right buttons to select it) and then press the A button. You should see the following list:

From here, scroll all the way down to raspi-config (yes yes, the shot above doesn't show this highlighted!) and press A. You'll get thrown back to a console and raspi-config will load up in all of it's ncurses-glory. From here, configure wireless and enable SSH. Note that you'll be back to standard keyboard key mapping, so don't try and use the A button... just stick with your standard cursors keys and enter... escape'ing when you choose the wrong adventure.

Meanwhile, if you happen to select the wrong wireless country, you can hit escape to the main menu and re-select it in the Localization sub-menu by selecting WLAN Country.

SSH is under Interfaces and, once enabled, the configuration app will ask you to reboot. Do this. Finally, SSH in with your favourite terminal client using the credentials pi/raspberry.

.***. Sunday, 5 September 2021, 10:51:22

***** Linux 5.4.72+ armv6l GNU/Linux

`***'

|*| Filesystem Size Used Avail Use% Mounted on

|*| /dev/root 30G 2.5G 26G 9% /

..|*|.. Uptime.............: 0 days, 00h14m35s

.*** * ***. Memory.............: 97496kB (Free) / 247472kB (Total)

*******@@** Running Processes..: 88

`*****@@**' IP Address.........: 192.168.1.57

`*******' Temperature........: CPU: 48°C/118°F GPU: 48°C/118°F

`"""' The RetroPie Project, https://retropie.org.uk

pi@classicpi:~ $

From here, let's cut over to the VGA display. This is done via the following:

pi@classicpi:~ $ cd ~/ pi@classicpi:~ $ git clone https://github.com/tianyoujian/MZDPI.git Cloning into 'MZDPI'... remote: Enumerating objects: 323, done. remote: Counting objects: 100% (32/32), done. remote: Compressing objects: 100% (22/22), done. remote: Total 323 (delta 15), reused 26 (delta 10), pack-reused 291 Receiving objects: 100% (323/323), 1.54 MiB | 599.00 KiB/s, done. Resolving deltas: 100% (165/165), done. pi@classicpi:~ $ cd MZDPI/vga pi@classicpi:~/MZDPI/vga $ sudo chmod +x mzdpi-vga-autoinstall-online pi@classicpi:~/MZDPI/vga $ sudo ./mzdpi-vga-autoinstall-online ... setup setup ... Setting up libgtk2.0-0:armhf (2.24.32-3+rpt1) ... Setting up matchbox-keyboard-im (0.1+svn20080916-12) ... Setting up libgail18:armhf (2.24.32-3+rpt1) ... Setting up libgtk2.0-bin (2.24.32-3+rpt1) ... Setting up libgail-common:armhf (2.24.32-3+rpt1) ... Processing triggers for man-db (2.8.5-2) ... Processing triggers for libgdk-pixbuf2.0-0:armhf (2.38.1+dfsg-1) ... Processing triggers for mime-support (3.62) ... Processing triggers for libc-bin (2.28-10+rpi1) ... ZERO-W CM 2B 3B 3B+ CM3 pi@classicpi:~/MZDPI/vga $ sudo reboot

From here, reboot and disconnect your HDMI screen.

System RAM

I did note that my system was only reporting 256mb total system memory when it had 512mb on-board?

pi@classicpi:~ $ free

total used free shared buff/cache available

Mem: 247468 48468 91656 2932 107344 146248

Swap: 102396 0 102396

Turns out the boot configuration is allocating 256mb to Video RAM!? Let's fix that... we don't need anywhere near that much RAM for a 640x480 screen. Here's the important part in /boot/config.txt.

[all] gpu_mem_256=128 gpu_mem_512=64 gpu_mem_1024=256

The three lines are the settings related to actual system RAM. We care about gpu_mem_512 and, as you can see, it's setting VRAM to 256mb! Change that to 64 and reboot. Don't try any lower as RetroPie will struggle badly.

Install Basilisk II

Jump back into SSH and start up RetroPie's setup application. Note that you can also do this through the front end if you're working directly on the unit.

pi@classicpi:~ $ ls RetroPie RetroPie-Setup pi@classicpi:~ $ cd RetroPie-Setup/ pi@classicpi:~/RetroPie-Setup $ ls AUTHORS COPYRIGHT.md logs README.md retropie_setup.sh CONTRIBUTING.md LICENSE.md platforms.cfg retropie_packages.sh scriptmodules pi@classicpi:~/RetroPie-Setup $ sudo ./retropie_setup.sh

From here, you'll be warned you shouldn't have paid for this... and I hope you didn't.

You'll find Basilisk II (package:basilisk) under opt and Mini vMac (package:minivmac) under experimental. Note you'll also find OpenTTD under opt... I might try that for fun. All packages will ask you a few questions, I always default to install from binary.

After installing each package, you'll be brought back to that packages sub-menu offering options for the already-installed package... without it telling you that it installed correctly. Slightly confusing, but just press the TAB key to get Back highlighted below and then hit Enter.

Go and install anything else you're after, whilst you're here, and then choose the reboot option at the bottom. You'll then get a final warning, of which you'll only need to heed if you've been tinkering with the front-end whilst waiting for this stuff to install... I should've mentioned above that you shouldn't do this!

So... reboot!

Configuring Basilisk II

This took a little bit of working-out before I got it how I liked it. Emulators on RetroPie have configuration/data in multiple places. ROMs (of which Basilisk II needs) are in the main users' (pi, in this case) home directory, whereas configuration is in the /opt/retropie folder. We'll be tinkering around everywhere to get this to work.

Although we've installed the Basilisk II package, the individual configuration file for it hasn't been created yet. To make it appear, we need to actually kick off Basilisk II once and let it error back to the RetroPie menu. Do this now by going back to RetroPie and selecting Start from the Macintosh menu. If everything worked, there'll now be a configuration file located in /opt/retropie/configs/macintosh/.

Next, download the fundamental items to get Basilisk II to work: ROM, OS 8.1 ISO. Expand both items locally and then copy them across to the ~/RetroPie/roms/macintosh folder. Rename the ROM file to mac.rom and the ISO file to anything you want, but make sure it matches the configuration below. Also make sure the CD image is read-only:

pi@classicpi:~/RetroPie/roms/macintosh $ chmod -w macos_81.iso pi@classicpi:~/RetroPie/roms/macintosh $ ls -l total 935696 -r-xr--r-- 1 pi pi 420229120 Sep 5 12:01 macos_81.iso -rwxr--r-- 1 pi pi 1048576 Sep 5 11:35 mac.rom -rw-r--r-- 1 root root 0 Sep 5 11:06 Start.txt

We'll also need to create a harddisk file which we will format and install OS 8.1 onto inside the emulator. The following command will create a 512mb blank file.

pi@classicpi:~/RetroPie/roms/macintosh $ dd if=/dev/zero of=disk.img bs=1024k count=512 512+0 records in 512+0 records out 536870912 bytes (537 MB, 512 MiB) copied, 63.6174 s, 8.4 MB/s

Note that we've called it disk.img. This is because the RetroPie configuration specifies this file on the command line and we'll just use that, instead of adding more config. We do have to do a few other configuration changes, so open up /opt/retropie/configs/macintosh/basiliskii.cfg with nano and update the settings as follows. Note that, if you want to change the allocated RAM, you should use a proper 8-byte value, so lookup the value here and update the config accordingly.

displaycolordepth 0 extfs / seriala /dev/ttyS0 serialb /dev/ttyS1 ether slirp udptunnel false udpport 6066 bootdrive 0 bootdriver 0 ramsize 67108864 frameskip 6 modelid 14 cpu 4 fpu false nocdrom false nosound false noclipconversion false nogui false jit false jitfpu false jitdebug false jitcachesize 0 jitlazyflush false jitinline false keyboardtype 5 keycodes false mousewheelmode 1 mousewheellines 3 dsp /dev/dsp mixer /dev/mixer ignoresegv false idlewait true disk macos_81.iso

The 'extfs' option defines the location of the 'Unix' drive that appears on the desktop. Note that, although there is an 'extfs' option configured above, RetroPie overrides this on the command line and sets it to the directory where we've just copied everything to. It's a great mechanism for copying files into the emulated machine, so you can copy extra things into this folder and then access them in Basilisk II. You can even do it while it's running... just close and re-open the Unix folder.

With the configuration saved, you should be able to choose start from RetroPie and ...

Hah, it booted and OS 8.1 is installing. Slowly!

Getting Audio Out Of A Pi Zero W

This wasn't easy! The Pi Zero W is a tiny board, missing many of the standard components so save cost. One of the components missing is an audio-out jack, but fortunately we can wire one up to the alread-in-use GPIO header. One note before you read any of the following: The pin numbering on the header is different to the connected pin numbers on the main CPU. Most of the time, when sites talk about GPIO18 or GPIO19, they actually mean the pin on the CPU and not GPIO Header pin 18 or 19! Grab and build the tools here and then run the gpio readall command:

pi@classicpi:~ $ gpio readall +-----+-----+---------+------+---+-Pi ZeroW-+---+------+---------+-----+-----+ | BCM | wPi | Name | Mode | V | Physical | V | Mode | Name | wPi | BCM | +-----+-----+---------+------+---+----++----+---+------+---------+-----+-----+ | | | 3.3v | | | 1 || 2 | | | 5v | | | | 2 | 8 | SDA.1 | ALT2 | 1 | 3 || 4 | | | 5v | | | | 3 | 9 | SCL.1 | ALT2 | 1 | 5 || 6 | | | 0v | | | | 4 | 7 | GPIO. 7 | ALT2 | 1 | 7 || 8 | 0 | ALT2 | TxD | 15 | 14 | | | | 0v | | | 9 || 10 | 0 | ALT2 | RxD | 16 | 15 | | 17 | 0 | GPIO. 0 | ALT2 | 0 | 11 || 12 | 0 | ALT5 | GPIO. 1 | 1 | 18 | | 27 | 2 | GPIO. 2 | IN | 1 | 13 || 14 | | | 0v | | | | 22 | 3 | GPIO. 3 | ALT2 | 0 | 15 || 16 | 0 | ALT2 | GPIO. 4 | 4 | 23 | | | | 3.3v | | | 17 || 18 | 0 | ALT2 | GPIO. 5 | 5 | 24 | | 10 | 12 | MOSI | ALT0 | 0 | 19 || 20 | | | 0v | | | | 9 | 13 | MISO | ALT0 | 0 | 21 || 22 | 0 | IN | GPIO. 6 | 6 | 25 | | 11 | 14 | SCLK | ALT0 | 0 | 23 || 24 | 0 | ALT2 | CE0 | 10 | 8 | | | | 0v | | | 25 || 26 | 1 | ALT2 | CE1 | 11 | 7 | | 0 | 30 | SDA.0 | ALT2 | 1 | 27 || 28 | 1 | ALT2 | SCL.0 | 31 | 1 | | 5 | 21 | GPIO.21 | ALT2 | 0 | 29 || 30 | | | 0v | | | | 6 | 22 | GPIO.22 | ALT2 | 0 | 31 || 32 | 1 | ALT2 | GPIO.26 | 26 | 12 | | 13 | 23 | GPIO.23 | ALT2 | 1 | 33 || 34 | | | 0v | | | | 19 | 24 | GPIO.24 | ALT5 | 0 | 35 || 36 | 0 | ALT2 | GPIO.27 | 27 | 16 | | 26 | 25 | GPIO.25 | IN | 0 | 37 || 38 | 0 | ALT2 | GPIO.28 | 28 | 20 | | | | 0v | | | 39 || 40 | 0 | ALT2 | GPIO.29 | 29 | 21 | +-----+-----+---------+------+---+----++----+---+------+---------+-----+-----+ | BCM | wPi | Name | Mode | V | Physical | V | Mode | Name | wPi | BCM | +-----+-----+---------+------+---+-Pi ZeroW-+---+------+---------+-----+-----+

So, there's a lot to take-in above. Note it's mirrored, so start outside-in when reading. On both outside columns are the GPIO pins of the BCM CPU. We're looking for 18 and 19 in these columns. Above, I've already actually configured the unit for sound, so you'll see that these are configured for ALT5. To understand ALT5, you can read the GPIO mappings here, but just understand that both need to be ALT5 for PWM to come out of 18 and 19. These then map to header-pins 12 and 35 respectively. You'll find these two numbers in the inner two columns on the table above.

Next, we'll need a bit of physical hardware to interface with the GPIO header. Fortunately, since I have used an old IDE cable, we already have a point to connect into! The IDE cable has the middle header on the Raspberry Pi, one end on the LCD and, on the final end, we'll need to tap into pins 35 and 12. From these pins, we'll wire into a low-pass filter as per the circuit schematic here.

The VGA project specifically left GPIO18 and 19 free to let us have audio out, but they aren't enabled just yet. To do this, we'll need to edit /boot/config.txt once more and tell it to send PWM out the required pins. Add the following line to the very bottom of the file:

dtoverlay=pwm-2chan,pin=18,func=2,pin2=19,func2=2

The first note here is that func2=2 somehow equals ALT5, which is what we want. The second is that, with any future changes of boot config by any software, you should review this file and make sure this configuration is still at the bottom! Once confirmed, reboot and double-check that headphones are selected in raspi-config.

Save and exit and see what happens when you test with:

aplay /usr/share/sounds/alsa/Front_Center.wav

If the sound is quiet, then use alsamixer to adjust the volume.

┌───────────────────────────────────────── AlsaMixer v1.1.8 ──────────────────────────────────────────┐ │ Card: bcm2835 Headphones F1: Help │ │ Chip: Broadcom Mixer F2: System information │ │ View: F3:[Playback] F4: Capture F5: All F6: Select sound card │ │ Item: Headphone [dB gain: 1.25] Esc: Exit │ │ │ │ │ │ │ │ ┌──┐ │ │ │ │ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ │▒▒│ │ │ ├──┤ │ │ │OO│ │ │ └──┘ │ │ 90 │ │ <Headphone > │ │ │ │ │ └─────────────────────────────────────────────────────────────────────────────────────────────────────┘

Bump the volume up to 90%.

Networking

So, TCP/IP to the internet should just work. AppleTalk to local ethernet devices probably won't work as AppleTalk packets don't survive over Wireless. I don't know why... but it's the same thing that happened when I was mucking around with physical LocalTalk adapters. Since I have another Pi on the network providing AppleTalk shares, I have the option to create a VPN and route AppleTalk over it to make it show up in Chooser auto-magically... but on a first attempt, the effort required is huge. I'll stick with manual IP entry for now, as that works fine!

The End Result

The screen is hilariously small, but games can be played!

The Pi Zero has just enough CPU to run OS 8.1 and A-Train. Audio works great and the MIDI sounds fine!

Shares are mounted via AppleTalk to the NAS and all is well!

IBM 45U0018 POS Keyboard

I saw this unit on eBay and couldn't resist. It really did remind me of the department store POS keyboards and I remember them being clicky. I checked the photos on the auction and saw that it had a non-standard socket and no cable included. You can download the drivers/configuration-utility here.

The main keys are fixed, but the surrounding keys have optional translucent key 'covers' where inserts have been placed for special functions. Some of them even cover standard keyboard keys.

But yeah, back to the socket, and do excuse the photo...

It's very similar to a standard IDC Header, but in-set which makes it really difficult to use anything other than IBM's proprietary cables. After a lot of googling, I found that there's both a USB and PS/2 cable version available.

Unfortunately, these weren't actually available anywhere... and if they were, the cost was out of control. It seems that these keyboards could also just dock onto the POS system above the till, so it's possible that the cable was only required if you wanted to mount the keyboard elsewhere. Anyway, a cable would be too easy... I'm sure we can work this out!

What does it look like on the inside?

With the hunch that the port supported PS/2 and USB, the keyboard was opened to work out the pinout. Opening it was actually very easy with just 6 small screws on the back. A large plate comes off and then there's just a bit of foil-cardboard shielding over the main circuit board.

Inside, of note, were a TUSB2046B IC and a STM32F103VBT6 Microcontroller with V0326_PF.bin programmed into it. The first IC happens to be the brains for a USB 4-port hub and provided a huge hint for determining the unit's wiring. I started tracing along the pins and the table below is the result.

Note that, when looking at the back of the keyboard into the socket when the keyboard is UPSIDE-DOWN on a flat surface, I've started Pin 1 from the top-right, with pin 6 then being top-left, pin 7 bottom-right and pin 12 bottom-left. This turned out to be silly as all the wires are in vertical pairs. Note this has been updated from the great resource at sharktastica.

| Pin # | Connected To | Notes | USB Cable |

|---|---|---|---|

| 1 | Pin 1 of T-46 aka TPS73633DBV | Voltage supply for the power regulator. Must be 5v! | Pin 1 - Red |

| 2 | Pin 1 of TUSB2046B | DP0 = Root port USB differential data plus. DP0 paired with DM0 constitutes the upstream USB port. | Pin 3 - Green |

| 3 | NC? | ||

| 4 | Pin 3 (or 6) of U4 | U4 is not populated. | |

| 5 | Pin 64 (PC7) of STM32F103VBT6 Microcontroller | PS/2 Keyboard Clock | |

| 6 | Pin 48 (PB11) of STM32F103VBT6 Microcontroller | PS/2 Mouse Clock | |

| 7 | GND | Pin 4 - Black | |

| 8 | Pin 2 of TUSB2046B | DMO = Root port USB differential data minus. DM0 paired with DP0 constitutes the upstream USB port. | Pin 2 - White |

| 9 | NC? | ||

| 10 | Pin 2 (or 7) of U4 | U4 is not populated. | |

| 11 | Pin 66 (PC9) of STM32F103VBT6 Microcontroller | PS/2 Keyboard Data | |

| 12 | Pin 52 (PB13) of STM32F103VBT6 Microcontroller | PS/2 Mouse Data |

Ok, so that's easy for the USB connection.. just wire the 'upstream' pins, +5v and GND into a spare USB cable. The other 2-pair of wires which run into the Microcontroller must be for the PS/2 mouse and keyboard? I wonder which is clock and which is data? There are plenty of images online showing microcontroller-to-PS/2-port hookups, so I'll try that after USB.

Hooking Up USB

USB cables contain 4 wires. First you need two wires for a very standard 5v DC rail and then you need two more wires to transmit and receive data. As you can see from the table above, we have all of these already mapped out. This was all very straight-forward thanks to the documentation for the TUSB2046B USB Root Hub IC. I grabbed a bunch of spare parts from the box'o'junk and started wiring something together. The USB cables I first tried to use happened to be power-only? No data lines! No wonder someone else threw them out.

Too short anyway! So instead, I remembered I had a mini USB socket in another tray'o'junk and set to wiring that up...

I plugged it into my RasPi 400 and it evicted all USB devices...

Sep 2 17:04:30 raspberrypi kernel: [63187.047153] usb usb2-port1: over-current change #1 Sep 2 17:04:30 raspberrypi kernel: [63187.202027] usb 1-1-port1: over-current change #1 Sep 2 17:04:31 raspberrypi kernel: [63187.278524] usb usb2-port2: over-current change #1 Sep 2 17:04:31 raspberrypi kernel: [63187.438880] usb 1-1-port2: over-current change #1 Sep 2 17:04:31 raspberrypi kernel: [63187.518607] usb usb2-port3: over-current change #1 Sep 2 17:04:31 raspberrypi kernel: [63187.678902] usb 1-1-port3: over-current change #1 Sep 2 17:04:31 raspberrypi kernel: [63187.758546] usb usb2-port4: over-current change #1 Sep 2 17:04:31 raspberrypi kernel: [63187.918864] usb 1-1-port4: over-current change #1 Sep 2 17:04:31 raspberrypi kernel: [63187.998562] usb usb2-port1: over-current change #2 Sep 2 17:04:32 raspberrypi kernel: [63188.238478] usb usb2-port2: over-current change #2 Sep 2 17:04:32 raspberrypi kernel: [63188.478480] usb usb2-port3: over-current change #2 Sep 2 17:04:32 raspberrypi kernel: [63188.718503] usb usb2-port4: over-current change #2 Sep 2 17:04:32 raspberrypi kernel: [63188.890074] usb 1-1-port1: over-current change #2

Ooops! Why am I chewing too much power? I google'd around and couldn't find an easy solution to inject my own power, as all answers indicated VCC needed to stay connected. Looking at my wiring again, I realised that this error was bound to happen as I'd wired the polarity around the wrong way! So, after correcting that...

Sep 2 18:44:47 raspberrypi kernel: [69203.309095] usb 1-1.3: new full-speed USB device number 9 using xhci_hcd Sep 2 18:44:47 raspberrypi kernel: [69203.443182] usb 1-1.3: New USB device found, idVendor=0451, idProduct=2046, bcdDevice= 1.25 Sep 2 18:44:47 raspberrypi kernel: [69203.443193] usb 1-1.3: New USB device strings: Mfr=0, Product=0, SerialNumber=0 Sep 2 18:44:47 raspberrypi kernel: [69203.449815] hub 1-1.3:1.0: USB hub found Sep 2 18:44:47 raspberrypi kernel: [69203.452677] hub 1-1.3:1.0: 4 ports detected Sep 2 18:44:47 raspberrypi kernel: [69203.779047] usb 1-1.3.4: new full-speed USB device number 10 using xhci_hcd Sep 2 18:44:47 raspberrypi kernel: [69203.922725] usb 1-1.3.4: New USB device found, idVendor=04b3, idProduct=4604, bcdDevice= 3.26 Sep 2 18:44:47 raspberrypi kernel: [69203.922734] usb 1-1.3.4: New USB device strings: Mfr=1, Product=2, SerialNumber=3 Sep 2 18:44:47 raspberrypi kernel: [69203.922741] usb 1-1.3.4: Product: IBM Retail USB Alphanumeric POS Keyboard Sep 2 18:44:47 raspberrypi kernel: [69203.922747] usb 1-1.3.4: Manufacturer: (c) Copyright IBM Corp. 2008 Sep 2 18:44:47 raspberrypi kernel: [69203.922752] usb 1-1.3.4: SerialNumber: 44T4011-200811231006420977000036 Sep 2 18:44:47 raspberrypi kernel: [69203.935428] input: (c) Copyright IBM Corp. 2008 IBM Retail USB Alphanumeric POS Keyboard as /devices/platform/scb/fd500000.pcie/pci0000:00/0000:00:00.0/0000:01:00.0/usb1/1-1/1-1.3/1-1.3.4/1-1.3.4:1.0/0003:04B3:4604.000D/input/input18 Sep 2 18:44:47 raspberrypi kernel: [69204.000545] hid-generic 0003:04B3:4604.000D: input,hidraw4: USB HID v1.00 Keyboard [(c) Copyright IBM Corp. 2008 IBM Retail USB Alphanumeric POS Keyboard] on usb-0000:01:00.0-1.3.4/input0 Sep 2 18:44:47 raspberrypi kernel: [69204.008558] hid-generic 0003:04B3:4604.000E: hiddev97,hidraw5: USB HID v1.00 Device [(c) Copyright IBM Corp. 2008 IBM Retail USB Alphanumeric POS Keyboard] on usb-0000:01:00.0-1.3.4/input1 Sep 2 18:44:47 raspberrypi kernel: [69204.016919] hid-generic 0003:04B3:4604.000F: hiddev98,hidraw6: USB HID v1.00 Device [(c) Copyright IBM Corp. 2008 IBM Retail USB Alphanumeric POS Keyboard] on usb-0000:01:00.0-1.3.4/input2 Sep 2 18:44:47 raspberrypi kernel: [69204.035363] input: (c) Copyright IBM Corp. 2008 IBM Retail USB Alphanumeric POS Keyboard as /devices/platform/scb/fd500000.pcie/pci0000:00/0000:00:00.0/0000:01:00.0/usb1/1-1/1-1.3/1-1.3.4/1-1.3.4:1.5/0003:04B3:4604.0010/input/input19 Sep 2 18:44:47 raspberrypi kernel: [69204.036075] hid-generic 0003:04B3:4604.0010: input,hidraw7: USB HID v1.00 Mouse [(c) Copyright IBM Corp. 2008 IBM Retail USB Alphanumeric POS Keyboard] on usb-0000:01:00.0-1.3.4/input5 Sep 2 18:44:47 raspberrypi mtp-probe: checking bus 1, device 10: "/sys/devices/platform/scb/fd500000.pcie/pci0000:00/0000:00:00.0/0000:01:00.0/usb1/1-1/1-1.3/1-1.3.4" Sep 2 18:44:47 raspberrypi mtp-probe: bus: 1, device: 10 was not an MTP device Sep 2 18:44:48 raspberrypi mtp-probe: checking bus 1, device 10: "/sys/devices/platform/scb/fd500000.pcie/pci0000:00/0000:00:00.0/0000:01:00.0/usb1/1-1/1-1.3/1-1.3.4" Sep 2 18:44:48 raspberrypi mtp-probe: bus: 1, device: 10 was not an MTP device

HAHA. It just worked. It's very loosely-clicky, but not bad at all. Hilariously sounds like the registers at David Jones. The trackpad and touchpoint actually work beautifully as well. Very impressive. I assume there's further commands that could be sent to change LEDs, use the peripherals, but I don't need it.

PS/2 Wiring

I didn't feel like plugging this into a PC and restarting it 17 times to work out the wiring, so I used an Arduino Uno instead! Unfortunately, no combination of pairs would get the unit to produce any output. I'll have to do some more digging at some point in the future... a cop-out, I know, but I'm happy with USB for now!

UPDATE: There's a pinout here at sharktastica.

Printing a proper plug

I searched Thingiverse and found a very nice set of IDC Plug Frames. I then dragged that frame into Tinkercad and stretched it to make it fit better. The result is here.

From there, I used standard 'single' jumper wires to build the 6x2 inner plug and glued them in place. I then soldered up a spare USB cable.

Perfect! Note there's still plenty of these keyboards on eBay from a WA seller. Highly recommended!

Dual Technologies SKD-4000

This beauty had been doing laps on eBay for a while. I had tried to low-ball it early on, only to receive a swift declination. A week or two later, I offered a little more and it was accepted! The seller took no time to send it to me, perfectly packed. It was listed as untested and with a cracked front-right case. Indeed it was, with one of the plastic clips actually hanging out the front of the opposing top-half, looking slightly like a buck-tooth.

After a little googlin', I came across a site talking about a slightly different version to this laptop. Turns out Dual Group were a Taiwanese manufacturer and built laptops that were then re-branded and on-sold. They therefore didn't really have their own site with any relevant info on this laptop. If anyone manages to find any information on this laptop, then please get in touch in the comments section! I therefore kept inspecting the unit, disassembling what I could prior to needing a screwdriver.

This unit didn't have a power supply, but thankfully the link above provided a pinout for the power supply their SKD-4000 needed. Under this unit, it stated it needed DC 20v @ 1.0A, so I tinned up a set of power wires and dialed in the voltage.

Jamming the wires in the power socket, after continuity-testing for GND, I flicked the power switch... lo'an'behold: the full orchestra of a vintage HDD and a POST beep!

The joy was very short-lived though... the BIOS quickly reported a low battery and incorrect date/time. Hardly surprising! I went into the BIOS anyway and did a HDD auto-detect.

116mb, nice! I saved the config and rebooted, but nothing seemed to have stuck. Seems I'll need to replace the battery to get further. Before that though, does VGA out work?

Nice! Ok, back to the CMOS battery. The link above provided a tear-down guide to help me, but in the end I didn't really need it as this laptop was surprising easy to open and work with! Even the CPU had a flap for easy access? It also has DIP switches for setting the CPU and they seem to configure the CPU pins directly? I'll try and decode them shortly.

The CMOS battery is a piece of work. It's hard-soldered in and it happens to be a rechargeable coin-cell. These are pretty rare nowadays... and... stupid me... I just tried to solder in a coin-cell holder and use a CR2032. DO NOT TRY AND USE NON-RECHARGEABLE BATTERIES IN-PLACE OF RECHARGEABLE BATTERIES!

Turning the unit on saw the coin-cell heat up rapidly, but fortunately I had my finger on the power switch, ready to prevent any spontaneous combustion. I then tried a 3.7v cell I had lying around, but the laptop started reporting 10 error beeps indicating that no battery was available at all. I really do hope I haven't trashed the charging circuit. At this point, I ordered an exact replacement Panasonic VL2330 battery and then looked for other things to fix up.

Power Plug

Whilst waiting for a battery to arrive, I realised I should solidify the power supply. Seems this type of plug is called a SnapNLock 4-Pin Mini DIN and I was pleased to see it available at Jaycar. I purchased a few (luckily) and attempted to wire one up. Soldering it was easy enough, but assembling it was next-level.

I mean, just look at the datasheet (which, actually, wasn't even east to find!), and you'll see what I mean... 8 components to jam together in a not-so-obvious order. I trashed the first plug and sorta-but-not-really succeeded with the second plug... it was good enough to test with.

Dip-Switch Dissection...

There are two blocks of four switches and, with no documentation, I set about trying to determine what these might control. Looking at the set closest to the CPU first, one can find the traces run off CPU pins.

Thanks to the glory of the internet, one can find pin maps and descriptions of pins readily available. The latter doesn't go into much detail, so actual CPU datasheets can also come in handy. After a little digging, it seems this block of switches controls maths error handling and interrupt line access to the CPU. I might just leave them as-is.

| Dip-switch Name | Solderable-jumper name | Connected CPU Pin | Pin Function | |

|---|---|---|---|---|

| JP1-1 | JP44 | B15 | NMI - Non-Maskable Interrupt | |

| JP1-2 | JP41 | Can't tell... but seems to toggle the signal from JP1-1 through to JP3. | ||

| JP1-3 | JP42 | A15 | IGNNE# - Ignore numeric error | |

| JP1-4 | JP43 | C14 | FERR# - Floating Point Error |

The second block's traces disappear into the board's layers and are impossible to trace and understand.

The BIOS

Just for fun, I popped out the PLCC32 and read it in my Willem Programmer.

You can download the BIN file here.

Back to that Battery

A proper Panasonic VL2330 arrived and I soldered it in place. Applying power heard the same beeping. Ok, let's follow the traces to the left and see what's going on... two diodes, both seem to conduct power... then the voltage goes into pin 20 of that IC... with no marking? Why no marking?

Under the right light, it turned out to be an Epson RTC-6593 Real-time Clock. It even has integrated battery-backed RAM! Of course, this unit stores my BIOS settings. Why has the label disappeared? It's COOKED! It tried to burn me when I touched it. We can only assume it's due to my testing of other batteries... if only I'd bought the correct replacement at the start.

Replacing the RTC

So, I'm game to try this... what I'm not game for is fake chips! Searching for this IC has only come up with seemingly-dodgy sellers on Alibaba and eBay. I've just thrown in a few orders and we'll see what comes back. In the meantime I've removed the existing IC and cleaned up the area. Interesting to note that the silk-screen shows the IC should be an RTC-6583, whereas a 6593 was installed. The datasheet seems to indicate that 659x has "Extended Alarms" whereas 658x doesn't.

During removal of the chip, I just happened to remove a pad... I blame the fact that the IC was actually glued down to the board! I couldn't work out why the IC wouldn't move, regardless of the pressure I applied. Furtunately, it was a quick fix with winding wire and it's ready to solder up.

I'll post a Part II once the ICs have arrived.

The Royal Express Visits Hokkaido (Again)

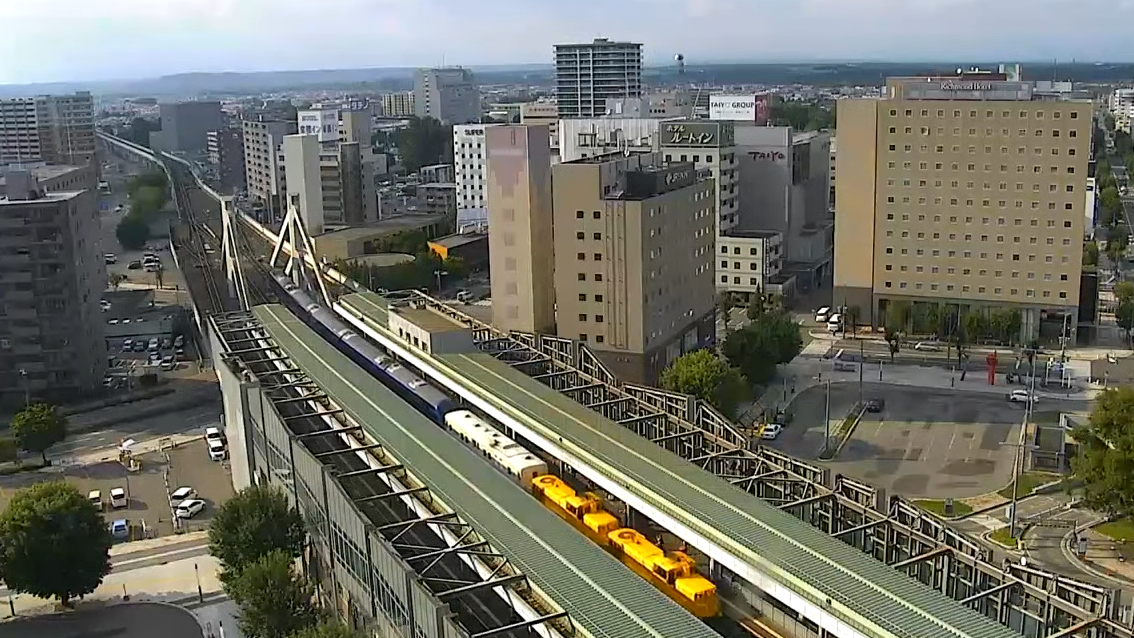

It's been a while, and there's a lot to post, but for now I'm catching up on trains. Actually, this isn't catching up at all... this train is touring Hokkaido as we speak. The Royal Express is a ridiculously beautiful electric set train that runs (usually) from Yokohama to Izu-Shimoda on the Izu Peninsula, but, due to Tokyu Corporation being perfectly adventurous, is running on non-electrified lines in Hokkaido!

It's an ELECTRIC TRAIN! You say? There's very few overhead wires in Hokkaido, you exclaim!? You'd be correct! To run this tour, they have employed two freshly-painted DE15 locomotives and a mail-car-come-generator-car painted in white, to (literally) tow the electric train through the beautiful pastures of Hokkaido.

Thanks to the current world order: we can't travel from Australia to Japan, but thankfully we can watch! Japan has a fantastic acclimation to rail-side webcams and a hotel in Obihiro has actually mounted one on their building with a perfect view of the station. The same team have also provided views of the airport and a famous bridge. Note that these links change all the time, so please just browse to their channel to find what they're offering!

Anyway, where was I? Oh yeah.. the tour train has actually already operated this route twice this season. Thanks to lockdown, I haven't been in any correct frame to be alert to its movements. Or maybe I was just working? The train passes the Obihiro Station webcam just after 4pm Australian Eastern Time and, well, it's knock-off for anyone starting on-or-prior to 8am.

Fortunately, I set my alarm today and caught it!

So yeah, double-DE15 + white power van + Royal Express EMU. Who would've ever thought to tow an EMU on 'genny'-power with two very light-weight diesels!? It's actually amazing on a many levels: reliability, engine-weight, loading-gauge... the list goes on.

Anyway, for those playing at home, Obihiro Station is a major freight-accepting town (the yard is further to the left/west of the camera), but has single-lines on either side. This means that, if you see a train, regardless as to whether it's meant to actually stop at Obihiro, it'll at least pause on the camera as there's line-working preventing it from proceeding. There are freight, Limited Express Tokachis (to the west) and Limited Express Oozoras (both directions) on the line at all times and there's always another service to wait for.

So yeah, it waited... and the westbound Oozora from Kushiro arrived.

Not long after, The Royal Express departed for Ikeda and the Oozora went onwards to Sapporo. From here it'll do a full loop, turning north at Kushiro (I want to do that next!) to Kitami and then back through Asahikawa. When this current world situation is over, I'll be doing the same!

Update: 04/09/2021

The Express De Royale has left on another lap, in delicious sunshine:

Enjoy patrons, enjoy.

DCC via an Arduino!

And now, back to the topic that started this entire blog: DCC! Back then, I was creating breadboard circuits to get a PC to talk DCC, and although it worked, it has now been made much easier thanks to the Arduino platform. All you need is a motor shield and an Arduino Mega! It seems that DCC on the Arduino started as a project named DCC++. Sometime around 2016, the 'great rewrite' occurred and DCC++EX was born. What follows is what's required to get this up and running in no time!

First off, you need a supported Arduino with a matching motor interface. My expectation is to use my PC to control the DCC trains, so I wont need any extra throttle hardware. For any electronics projects, make sure you have a solid power supply. Especially with DCC, which requires intricate signals running over the model railway rails, you should follow the power supply guidelines here, preventing any further issues.

To make life easy, I purchased a legit Arduino Motor Shield from Core Electronics and attempted to plug it into my Arduino Mega 1280... used in most of the Arduino posts on this blog.

Turns out, my Mega is so old that the pins don't even line up! Seems that the pin layout changed at some point in the last 11 years.

Luckily I had a spare Uno on-hand from previous Remote Control tinkering.

With the newer Uno, things fit together nicely...

Note that there's still a mod required on the motor shield to make sure that you isolate the USB power from the track power.

Following the instructions here, I cut/scratched the thin trace between the VIN pads on the board. With the pads still there, I can solder a jumper wire on later if I want to restore the use of the Arduino's voltage input.

Once you've got your hardware setup, plug it into your PC and make sure the Arduino interface is all up-and-running, including the installation of the Arduino drivers. You can then go and download the latest version of CommandStationEX. Extract the zip and open the folder, you'll find the PDE is associated with the Arduino IDE and can just be double-clicked. Finally, just make sure your Arduino is configured correctly (type/port) in the IDE and upload the sketch.

Note that the software above is just the code for the Arduino. The Arduino acts as a bridge, with its own command set, so you'll then need a controlling application to get trains moving. I downloaded and extracted WebThrottle-EX, but you don't even have to do that! On the computer connected to the Arduino, just run it from the cloud!

Firstly, hit Connect in the top-right. It'll ask you to choose a Serial Port, which USB2Serial should be listed. Mine was COM6 and it all connected straight away. From there, hit the Power Switch in the middle. Finally, you need to enter the vehicle ID in the top left and then hit the arrow to the right of it. Thanks to my record keeping, I knew the ID I'd set the Kirara to. With the number 12 in place, I toggled the headlights button and the headlights came on! The track was dirty and the vehicle wheels were too, so I flipped it over to clean and found...

Hah! I left a note to myself that I hadn't even seen this time-around.

I didn't need N Scale to work this time around, so I packed it all up in ready for a HO DERM install! Mission accomplished!

Mega Drive Circuit Board Repairs

A bunch of Sega Mega Drives came via the workbench recently, all looking for a 50/60hz mod and region unlocking. Two older Mega Drive 1s were in the batch and the first modded with zero concern. Unfortunately, the second wouldn't even boot... a quick opening of the case saw the reason:

This area of the circuit board is easily accessible from the cartridge slot and I can only assume that a screwdriver (or other sharp object) has been jammed in at some point, destroying a few traces. You'll also notice solder to the left, but that was me in a previous attempt to repair this. I tried again as I now have a USB Microscope and it really does work well for reviewing damage and making intricate repairs!

How not to repair it

I first-up thought I'd be able to use copper winding wire and simply solder to each pad where the IC contacts the circuit board.

From the shots above, you can see how quickly that process failed. The combination of using a soldering iron under a microscope, a large soldering tip and shakey hands meant that solder spread everywhere. Fortunately, solder wick cleaned all that up in no time.

Also how not to repair it

The next method was a little dodgy, but proved successful. From above, I knew i needed more room to solder, so the goal was to create this room by lifting and spreading the pins and running wires to the other end of the traces.

A multimeter found the other end of the traces and winding wire was attached.

Thanks to the tiny tweezers in the iFixit kit, I was able to bend, lift and then straighten the leftmost leg.

From there, the other legs were lifted easily.

Finally, they were all spread out both horizontally and vertically to make soldering as easy as possible. I then connected the right-most as it was only going as far as the local via.

With the wires hideously attached, I considered bending the legs back down... But a blind person could see my dodgy soldering job would make contact.

Instead? Glue gun to the rescue! Finally? Test. It worked!

Kangaroo Liner でGO!

2021's Timetable Revision is full of more surprises! First we had the innauguration of the new Fukuyama Rail Express from Ajikawaguchi to Morioka. Next up we have a new service known as the Kangaroo Liner, run by the Seino Group, from Nagoya to Fukuoka! The train is named after the companies' logo. Something quite similar to QANTAS, but backwards.

Above is the stock image that was sent out with all media online. I was very surprised to see a DF200 up-front... so-much-so that I thought there'd be a chance one would run the service! The media releases indicated that the train wouldn't be full of Kangaroo-only containers and that there'd be space available for other operators to hitch a ride.

| Location | Northbound | Southbound (read upwards) |

|---|---|---|

| Service | 5051 | |

| Nagoya Terminal | 2212 | 1823 |

| Inazawa | 2229-2237 | 1721-1804 |

| Gifu | 2258-0007 | 1559-1655 |

| Suita | 0201-0204 | 1245-1250 |

| Kobe | 0238 | 1210 |

| Himeji | 0309 | 1135 |

| Okayama | 0423-0432 | 0911-0957 |

| Hiroshima | 0646-0649 | 0554-0601 |

| Iwakuni | 0734 | |

| Shinanyo | 0850 | 0409 |

| Hatabu | 1028-1040 | 0219-0244 |

| Kita-kyushu | 1056-1106 | 0125-0202 |

| Fukuoka Terminal | 1247 | 0022 |

| Service | 5050 |

Westbound Service

The first train to leave was the westbound service from Nagoya to Fukuoka. At 2012 on March the 29th, the service departed and passed the Nagoya Station Camera not long after.

As you're watching the start of the video, you might be ready to tell me that it's "not the right train!"... but as the consist keeps rolling through the camera, you'll see that the Kangaroo-liveried containers are all piled on the rear. As mentioned above, there was always going to be spare room on the rake of flat wagons and the company was very happy to accommodate other operator's containers.

After travelling west, it then passed the Mukomachi Live Cam with quite a few more Kangaroo containers on-board!

From here, the Shin-Osaka cam picked it up, but it there was less-than-zero visibility. Unfortunately, there's no other cameras to the west to capture the action!

Eastbound Service

Due to this limited visibility out west, the first spot the train was seen was the Shin-Osaka Live Cam. The eastbound service seems to have at-least half a loading of Kanga-tainers.

After a stop-over at Suita, the train passed the Mukomachi Live Cam on time.

And then finally, back through the Nagoya Station Camera.

Looking forward to seeing these in real life... at some point... in the distant future.

Apple eMate 300 – Battery Refurb

Whilst fixing the hinges in my eMate 300, I noticed that there were also links to replacing the batteries. That link shows how to replace with proper cells, but it turns out that you could also use a battery holder.

I bought a full kit of bits to do the latter, but then realised that the installation required hacking out the existing cage for the battery. Not wanting to do this, I fell back to the soldering idea and wished I'd bought batteries with solder tabs instead of just standard AA-style cells.

Anatomy of a Battery Pack

The eMate 300 battery back has a socket with 5 pins/4 wires, a thermistor, 4 cells and a temperature switch at the far end. When replacing the cells, remember to keep everything but the actual cells themselves.

Peel the plastic off and then de-solder or cut all contacts. And keep the temperature switch!

Solder everything back together in the same order...

And then jam it back in the plastic case that it all came in...

If you're in luck...

You'll have a charging battery!

Testing it...

There doesn't seem to be an SSH client for the Newton (although people have tried), so I thought I'd go for Telnet. It seems easy to do over a serial cable, but I want to do it over Wifi! Thankfully there's the PT100v1.1 Client available over at United Network of Newton Archives.

Installing this got me a prompt... but a swift disconnection when trying to log in. But, the battery is still showing full charge after minimal use over two days! Win.

Fukuyama Rail Express でGO!

The Fukuyama Rail Express is an express rail-freight service run by Fukuyama Transporting Co, Ltd. Regarding rail-freight, they previously only operated a service from East-Fukuyama to Tokyo.

Here's a shot of that service from my travels in 2019, running past Shin-Osaka Station behind an EF66.

As of yesterday, a new service has been innaugurated from Ajikawaguchi (Osaka) to Morioka!

How bad is my photoshop? Note that the services only run on weekdays.

| Location | Northbound | Southbound (read upwards) |

|---|---|---|

| Service | 58 | |

| Ajikawaguchi | 2208 | 1600 |

| Suita | 2227-2231 | 1516-1528 |

| Gifu | 0023 | 1257 |

| Inazawa | 0038-0040 | 1229-1234 |

| Kasadera | 1206 | |

| Nishi-Hamamatsu | 0200 | 1025 |

| Shizuoka | 0259-0301 | 0902-0910 |

| Yoshiwara | 0826 | |

| Numazu | 0337 | 0747-0749 |

| Sagami | 0421 | 0656 |

| Yokohama | 0449 | 0629 |

| Shin-Tsurumi | 0505 (arrive) | 0615 (depart) |

| Loco swap and service change to 61 | Loco swap and service change to 59 | |

| Shin-Tsurumi | 0541 (depart) | 0541 (arrive) |

| Kajigaya | 0551 | 0532 |

| Niiza | 0625 | 0502 |

| Omiya | 0642 | 0449 |

| Utsunomiya | 0745 | 0351 |

| Kuroiso | 0838-0842 | 0259-0303 |

| Koriyama Terminal | 0931-0954 | 0007-0158 |

| Iwanuma | 2234 | |

| Sendai | 1147-1207 | 2141-2215 |

| Higashi-Sendai | 1217 | 2134 |

| Kogota | 2051 | |

| Morioka | 1433 | 1908 |

| Service | 60 |

Thanks to Japan's love of live-cameras, I was able to follow the service in both directions. Actually, as I start to write this post, both trains are still running both north and south. Anyway, let's rewind and check out what happened.

Light Engine to Ajikawaguchi

The northbound service started at Ajikawaguchi, just next to Universal Studios Japan in Osaka. To get the rake of beautifully-shiny containers out of the port, an engine was needed. EF210-156 was sourced from Suita and sent to Ajikawaguchi at around 1930 on the 23rd of March, 2021. Here it is passing the Shin-Osaka Live Cam.

It then passed the webcam near Fukushima Station.

Ajikawaguchi to Morioka

With the loco in place, the next step was to run the service! The consist ended up passing the Fukushima Camera around ~4 minutes behind schedule thanks to a late-running Haruka Airport Express.

Back to the Shin-Osaka Live Cam, it was nearly impossible to see it pass... but the audio is awesome in the night air!

Next up, it passed the Mukomachi Live Cam, amongst all the other freights and services.

A while later, it passed through Nagoya Station. Note the Shinkansen track vehicles working away also. That's a huge Tamper!

There's a great cam between Fuji and Shizuoka (which I've discussed before, recording times) and the train was seen passing through.

As that the train took the Niiza route through Tokyo, we couldn't see it on the Akabane or Shinjuku Cameras. Therefore the next and final camera was the Omiya Camera. The EH500 would've been swapped on at Shin-Tsurumi.

And that was it for the northbound. Congratulations Fukuyama Transport! Fortunately, we still had the southbound to stalk.

Morioka to Ajikawaguchi

The southbound left Morioka on the same night at 1908. It therefore passed the Omiya Camera before the northbound at around ~0450.

Whilst waiting for it at the Fuji cam, the northbound original Fukuyama Rail Express from East-Fukuyama passed by!

A little while later, the southbound was seen passing.

Next up was Nagoya Station.

And another guest came through an hour later...

And then again at Mukomachi Live Cam, right up the back, top-right, look really close!...

And since we're still waiting for the Fukuyama Rail Express to get to Mukomachi, here's Doctor Yellow passing Torikai to Shin-Osaka.

Whilst 'waiting at Mukomachi Live Cam', an EF65 passed towing a DD200!

And then, the main event at Mukomachi Live Cam.

Back through the Shin-Osaka Live Cam.

Through the Southern-Side Shin-Osaka Cam, one minute earlier if you believe system clocks... Also, this camera was down the previous evening when the inaugural service ran...

And then the final shot of the day! Past the Osaka Loop Line at Fukushima.

And that's a wrap!

Melbourne BG SCS Train Timetable

Melbourne BG SCS Train Timetable